During my career talking with architects, contractors, and consumers about acoustic construction, I’ve always finished the conversation with a short “sermon” on sound flanking. Too often, the focus is on the assembly that gets the highest STC or IIC rating, but less attention is paid to sound flanking issues. Once a design is executed in the field, sound flanking issues can potentially derail the original acoustical goals. To achieve the best results, attention to sound flanking is critical in the project design and construction phases.

So, what is sound flanking anyway?

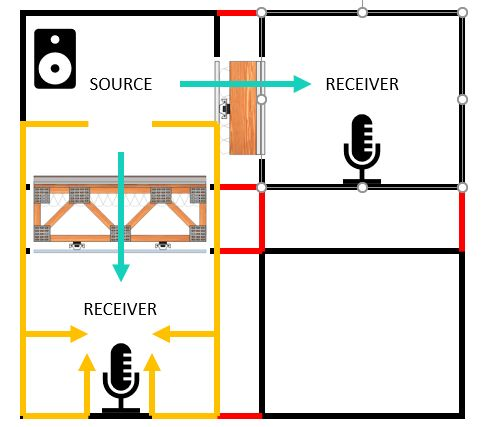

As sound travels from one place to another it behaves like water in that it tends to find the path of least resistance. Sound will find a way to leak through openings, or go around, over or under a barrier, or through mechanically connected components.

Imagine if you built a boat of wood planks but did not seal the joints between the planks. In no time, the water would leak through the unsealed joints and your boat would fill with water and sink! In the same way, building high-performance acoustic assemblies without acoustically sealing the joints, penetrations, or otherwise addressing flanking issues can seriously impact the STC and/or IIC performance of your carefully designed assembly!

The water analogy following the path of least resistance can be used to look at your assembly designs, floorplans, and construction details to address sound flanking issues in your design.

What products can help reduce these flanking paths?

1. Joints or gaps should always be sealed with an acoustically rated non-hardening caulk or sealant. Be sure it’s also rated for fire and smoke where required.

2. Electrical outlets are classic flanking paths/penetrations and should be sealed with acoustical putty pads applied around the back of the junction box before the drywall is installed.

3. Isolated gypsum board such as a wall or ceiling isolated on RSIC-1 sound clips require a small gap between the isolated panels and the adjoining walls or ceiling. Resilient foam tape such as PAC International’s RSIC Perimeter Tape can be applied into larger gaps and then sealed with acoustical caulk.

4. Structural flanking paths between wall and floor framing can be addressed by using products such as the RSIC-WFI system or the RSIC-U that isolate the top and bottom plate of a wall from the surrounding structure.

5. Structural flanking paths can also occur when heavy objects are mounted on acoustically isolated walls or ceilings. In our last Tech Tuesday post (11/22/2022), we talked about the PAC-RCB product that maintains the acoustic isolation of resilient channels walls when mounting heavy objects like cabinets.

Have sound flanking issues ever created challenges for a particular project you were involved in and if so, what sort of things were done to resolve these issues?

#construction #apartments #hotels #noise #noisecontrol #flanking