Let’s face it – resilient channels (RC) are a reality we must deal with despite the myriad challenges they present for maintaining quality construction. The propensity for RC to be short-circuited when gypsum board is attached is well known, but there are many other design and installation issues with RC. For a great overview of the RC design and installation challenges, check out the articles by Ben Wolf of ABD Engineering & Design [1]. Sound isolation clips like the RSIC-1, RSIC-V, and RSIC-SI-X are the best way to ensure the quality of noise barrier assemblies, but many projects just cannot (or will not) pay the premium for better performance. As we move into 2023, market forces will push more projects toward RC as apartment rent growth slows, the cost of financing continues to increase, and product availability and labor shortages continue to weigh on the industry.

One common issue with RC is the plethora of makes and models available on the market. Typically, having lots of options is a good thing, but with RC it presents one specific challenge: design specifications typically refer to one proprietary make and model of RC that has been shown to provide better acoustical performance than the alternative RC makes and models. The difference in performance is not small. In their recent Noise-Con 2022 paper “Quantitative comparisons of resilient channel designs in walls and ceilings,” Wayland Dong and John Loverde, FASA of Veneklasen Associates, Inc. [2] showed that the cheaper RC underperformed the premium RC from the same manufacturer by an average of eight (8) IIC points and three (3) STC points when tested on an 18″ open-web wood truss floor/ceiling assembly. Furthermore, while all the listed assemblies with the premium RC exceeded the code minimum of IIC 50, all the listed assemblies with the cheaper RC failed to achieve the code minimum.

As market forces likely push more projects towards RC – and recent testing shows the danger of using cheaper RC – there is one more issue that adds up to make RC a significant challenge for projects: the premium RC shown to perform the best acoustically is often unavailable, on allocation, or requires long lead times for the necessary quantities for a project. This creates a perfect storm in which, when the specified RC is not available, the project budget cannot stretch to accommodate the RSIC-1 – and using whatever RC is available can significantly degrade the acoustical performance and result in non-compliance with the building code’s acoustical requirements.

This is where PAC’s RC-1 Boost can save the day, as it did recently for the Novel Ballantyne project by Crescent Communities [3]. The RC-1 Boost was designed to work with all RC to improve its acoustical performance. PAC’s extensive laboratory testing shows that the RC-1 Boost consistently improves the acoustical performance of alternative RC so that it meets or exceeds the performance of the premium RC without Boost [4]. Specifically, the RC-1 Boost consistently added five (5) IIC points for all the RC makes and models PAC tested. The IIC results are more important because that is where the Veneklasen testing showed the biggest differences – and because it is typically much harder to achieve the code minimum for IIC than it is for STC. On the Novel Ballantyne project, the specification was for the typical premium RC, but it was not available in time for the project. When the drywall contractor reached out for alternatives, the project’s acoustical consultant, Nicholas Block of SLR Consulting, recommended PAC’s RC-1 Boost which did the trick to keep the project moving while maintaining the acoustical performance goals.

PAC’s RC-1 Boost can also be used with premium RC to achieve higher acoustical ratings. Testing has shown that adding the Boost to premium RC also raises its IIC ratings by five (5) points. Acousticians typically give acoustical ratings in tiers separated by 5 IIC points, with the code minimums of STC and IIC 50 reserved for student housing and inexpensive apartments. STC and IIC 55 are commonly recommended for market-rate apartments, and STC and IIC 60 (or higher) are usually recommended for condominiums. Similar tiers are outlined in the International Code Council’s “ICC G2-2010 Guideline for Acoustics.” [5] This means that adding the RC-1 Boost is a simple and cost-effective way to move a project’s acoustical performance to the assembly.

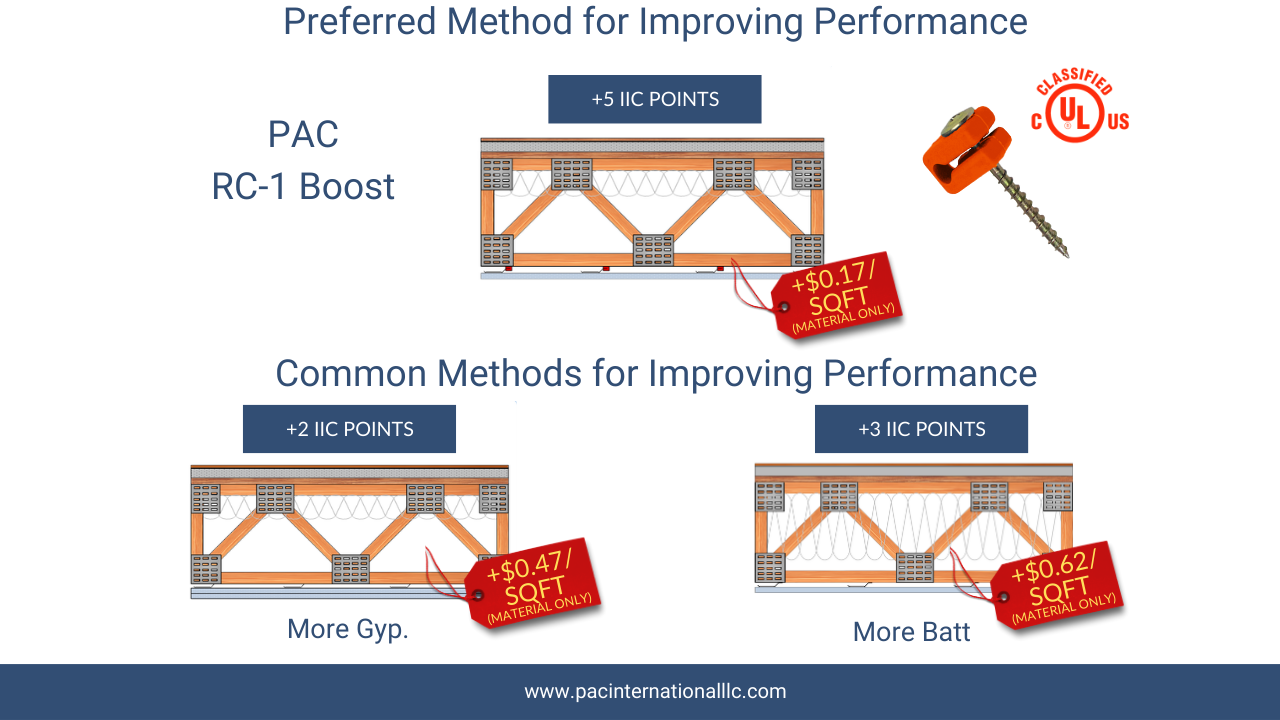

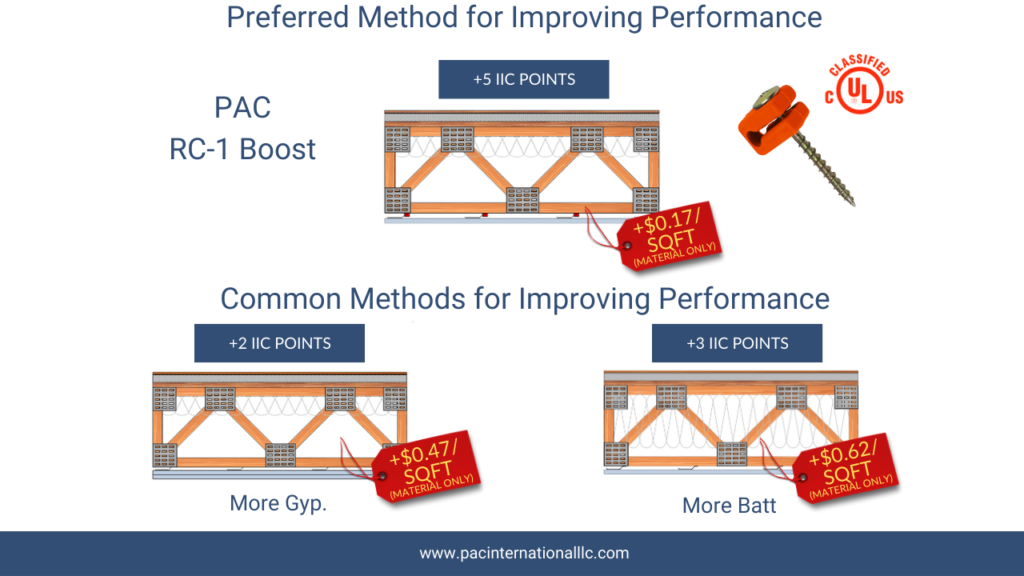

Commonly, when an acoustician is looking to increase the IIC ratings on a project with RC they will look at one of the following options: 1) increasing the thickness of batt insulation, or 2) adding a layer of gypsum board. Gypsum board and batt insulation are common building products that are already on the project, so adding more seems like an easy and affordable option, but the additional costs can be surprising. Based on 2022 pricing in Oregon, adding a second layer of gypsum board costs an additional $0.47/sqft in materials alone, and increasing the batt insulation thickness from R-11 to R-30 adds $0.62/sqft in materials. By comparison, the PAC RC-1 Boost costs only $0.17/sqft and it can achieve the highest IIC rating of these three options.

In summary, the PAC RC-1 Boost solves two common problems on projects. First, it provides a readily available alternative to premium RC that does not increase project costs. Second, the RC-1 Boost is the most cost-effective way to increase the IIC rating of an assembly.

References

1. Resilient channel issues

a. “Resilient Channel in Design,” Benjamin Wolf, ABD Engineering & Design (https://www.abdengineering.com/blog/resilient-channel-in-design/)

b. “Resilient Channel Installation,” Benjamin Wolf, ABD Engineering & Design (https://www.abdengineering.com/blog/resilient-channel-installation/)

2. “Quantitative comparisons of resilient channel designs in walls and ceilings,” Wayland Dong and John LoVerde, Noise-Con 2022 (https://doi.org/10.3397/NC-2022-757)

3. Novel Ballantyne – Crescent Communities case study (link)

4. RC-1 Boost brochure – sample acoustical testing results (https://pacinternationalllc.com/Products/RC-1%20Boost/RC-1%20Boost%20Brochure%2010-22.pdf)

5. “ICC G2-2010 Guideline for Acoustics” (https://codes.iccsafe.org/content/iccg22010/icc-g2-2010-acoustics)

#multifamily #acoustics #noisecontrol #architecture #apartments #construction