PAC FREQUENTLY ASKED QUESTIONS

Got questions about noise and vibration isolation products?

We’ve got you covered!

Whether you’re a curious customer or a seasoned pro, we are here to provide you with engaging information with acoustics in mind. and discover the ins and outs of noise and vibration.

Do I need RSIC Clips on both sides of the wall?

There are situations where clips should or can be used on both sides of a separation wall. If your wall connected directly to the joist or frame above, there may be flanking or direct vibrations resonating from the ceiling down the wall framing. Additional concerns may be plumbing lines in the shared wall. The pipes should be wrapped to reduce the fluid flow noise, but may still have residual noise from the plumbing connections to the frame, which may transmit energy to the direct connected gypsum board side.

Most of the time the noise control for walls is only dealing with room to room (side to side) noise. If this is the only concern, then RSIC-1 clips are only needed on one side of the wall. We have tested RSIC-1 clips for STC on a wall from both sides. See Riverbank acoustic lab tests. TL01-208 and TL01-209. The STC is 56 on a wood framed wall for both tests. We do recommend the clips be placed on the noisy side of the room to help reduce vibrations in the structure. This helps reduce flanking noise through the framing.

Pac International, LLC has tested wood framed walls with Resilient Sound Isolation Clips (RSIC-1) on both side of the same wall. The net result was a -2 points in STC reduction over the Resilient Sound Isolation Clip (RSIC-1) installed on one side only.

Along the same line of conversation, the question arises: When I install the Resilient Sound Isolation Clips (RSIC-1) on one side of a wall, which side should I install the RSIC-1 clips?

PAC International, LLC has tested RSIC-1 for STC on a wall from both sides, the noise source side and from the noise receive side. See Riverbank Acoustic Laboratory tests: TL01-208 and TL01-209. The STC is 56 on a wood framed wall for either tests.

PAC International, LLC recommends the clips be placed on the noisy (source) side of the wall to help reduce vibrations from reaching the structure. This helps reduce flanking noise through the framing.

LIIC – Low Impact Isolation Class. What does it really mean?

Information from Concrete Products publication. Link below.

Wood structures’ newest red flag: ASTM floor noise standard – Concrete Products

A new standard from ASTM Committee E33 on Building and Environmental Acoustics establishes an evaluation metric for low-frequency impact noise, especially the thudding from footfalls typical in multi-level buildings constructed of materials other than cast-in-place or precast concrete.

The new ASTM E3201-21 standard will net formal ratings for tenant or occupant footstep noise—one of multi-level wood buildings’ most pervasive nuisances.

“When inside a wood-frame or other lightweight building, one can hear heavy footsteps from other occupants, which is usually described as thudding,” says Samantha Rawlings, associate principal at Santa Monica, Calif.-based acoustical consultant Veneklasen Associates and technical contact for the new ASTM E3207-21, Standard Classification for Determination of Low-Frequency Impact Noise Ratings. “Using this standard opens a door of design capability that has not existed in more than 60 years of evaluating impact noise from footfalls in buildings.”

E3201-21 can be used in conjunction with data gleaned from ASTM E3222-20a, Standard Classification for Determination of High-Frequency Impact Sound Ratings. The classifications will assist stakeholders throughout a project’s value chain, from developers, engineers, architects and contractors to laboratories, regulatory bodies and sustainable rating system entities. The World Health Organization identifies excessive noise within residential housing as having negative effects. E3201-21 promotes public health by providing additional tools for building designers to create quiet living that will benefit communities worldwide.

Are steel joists hard to isolate? What is the best products to use?

Steel joist structures can be especially hard to design for good STC and IIC ratings. They are lightweight, flexible, and steel is a great transmitter of sound. Not long ago, PAC was asked to help provide solutions for a condo project that was built using C-section steel joists. Tenants had begun moving into the high-end condominiums and the owners were NOT happy with the acoustical performance.

To help solve the problem, PAC teamed up with @Ecore and @PABCO to conduct a series of acoustical tests at @Intertek in York, PA. Using PAC’s 1” deflection RSIC-SI-1 Ultra springs along with @Ecore’s QT underlayment and @PABCO’s gypsum board we were able to achieve STC and IIC ratings over 60 and provide the quiet environment the owners expected.

See below for a couple assemblies from the testing program. For more assemblies and additional information, check out PAC’s Assembly Selector at www.pacinternationalllc.com.

Do I need a perimeter gap around ceilings?

The RSIC installation guide calls for 1/4″ gap between the ceiling gypsum board and the perimeter of the ceiling. This gap should be filled with acoustical caulking. The gap is then taped and finished like a regular ceiling / wall intersection. The caulking provides two functions. It fills the void and bonds the ceiling to the wall with a flexible material ensuring an airtight ceiling. The airtight ceiling stops noise from flanking around the gypsum board and through what may be a weak area of the ceiling. The second function ensures that in the event of movement, the corner will remain sealed. Typically mud is pushed into the corder and tape is placed over the mud. This drywall mud creates an initial hard bond between the wall and ceiling. If there is any movement, that bond can be broken, resulting in a gap that leaks noise.

How do you decouple one wall from another?

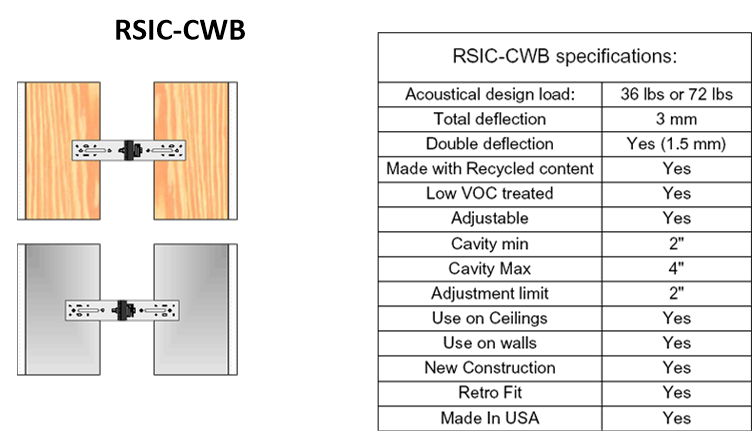

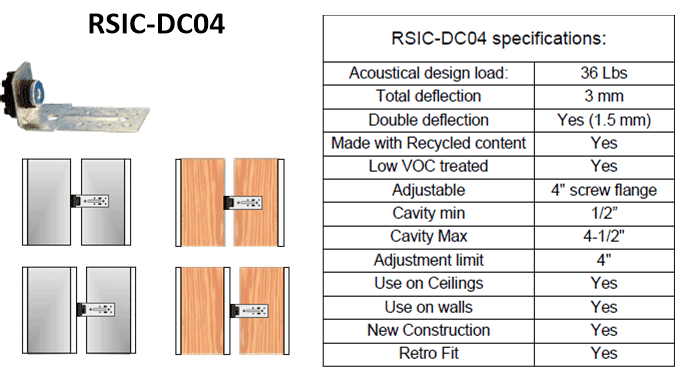

The RSIC-CWB and the RSIC-DC04 can both be used to isolate one framed wall from another. Both the RSIC-CWB and RSIC-DC04 items are available in 36 Lb and 72 Lb acoustical load ratings. The RSIC-DC04 X2 HD has an acoustical load rating of up to 144 Lbs.

For more information please visit the RSIC product page, email, or call our staff for additional information.

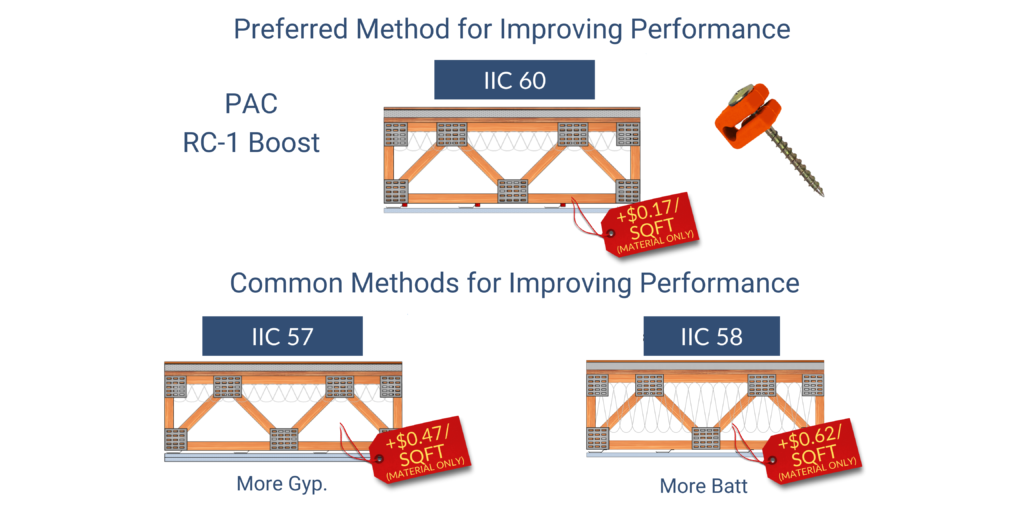

RC-1 Boost on ceilings. How much does it improve IIC?

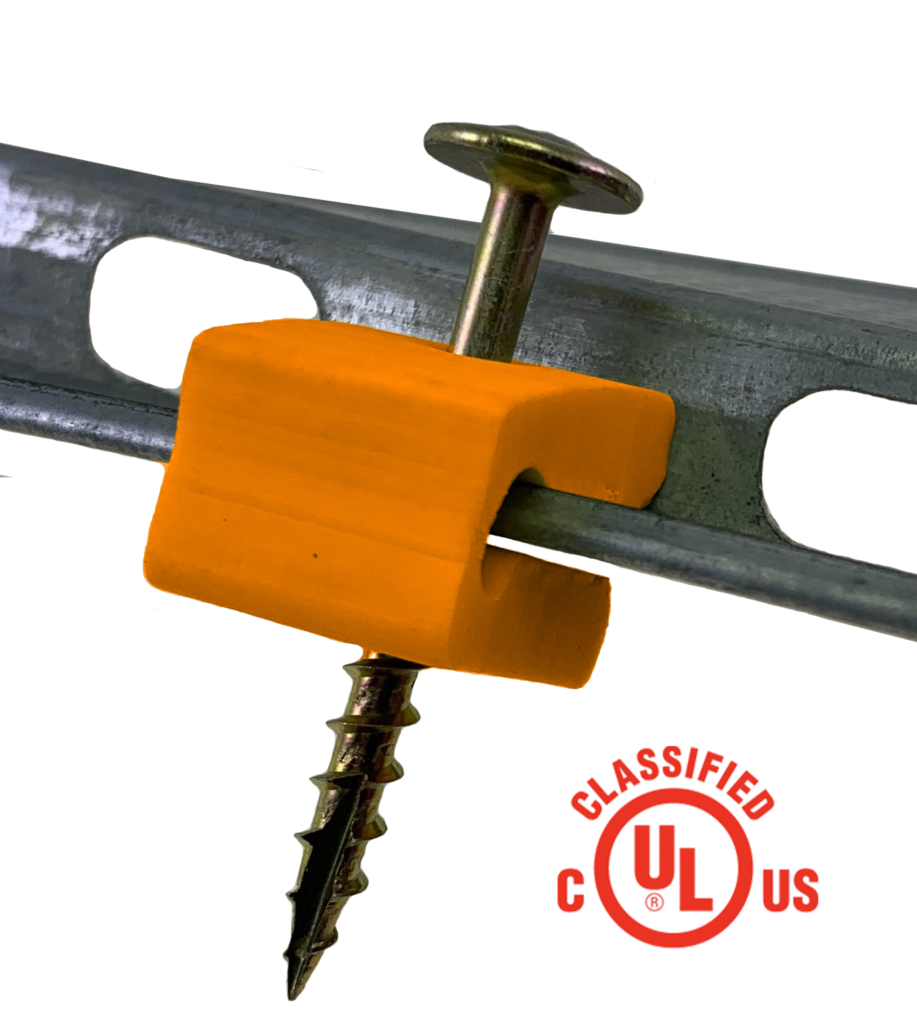

The RC-1 Boost is the new resilient product in the game of noise control focused primarily wood framed on multifamily construction. The made in USA innovative design allows the RC-1 Boost to be used on all brands and types of Resilient channel.

The RC-1 Boost with one layer of 5/8″ gypsum board achieves a 7 IIC point increase over RC-1 channel alone, and a 5 IIC point increase when added to RC-Deluxe channel.

BASE ASSEMBLY

RC-1 Boost is the most cost-effective way to improve the IIC rating of common floor/ceiling assemblies with resilient channels.

PAC’s testing shows that adding the RC-1 Boost can consistently provide a 5-point increase in the IIC rating of assemblies with resilient channels. This makes the RC-1 Boost a less expensive and more effective means of improving IIC ratings when compared with the typical methods of adding batt insulation or gypsum board layers.

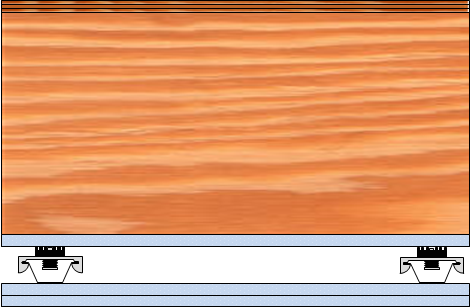

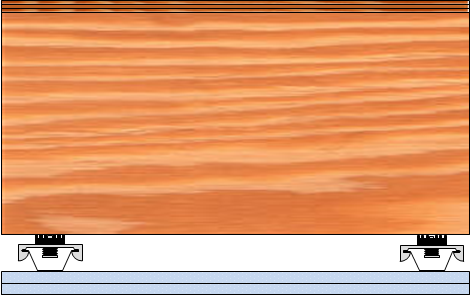

Can I use the RSIC-1 to retrofit a ceiling?

A question came across my desk today asking if you can retrofit RSIC-1 over an existing ceiling? The simple answer is no, you can not achieve the desired acoustical results when the RSIC-1 is installed directly under an existing ceiling. You can physically install the RSIC-1 Retro under an existing ceiling, but with substantially handicapped results. Below is a ceiling that has the RSIC-1 installed under an existing ceiling. This creates what’s called a triple leaf ceiling. These types of ceilings typically have not performed well acoustically.

The Correct way to build an acoustical ceiling with minimal impact to the bottom line is to tear off the existing gypsum board, add insulation if needed, and install a new ceiling using the RSIC-1 clips. This has shown to increase the acoustical performance of ceilings by up to 15 IIC points. That means you ceiling will transmit 70% less noise. I have attached an image below, for a reference. The difference can seem daunting, but the increased cavity above the gypsum board helps the RSIC isolator increase performance.

RSIC Joist Isolators and Floating Floors

The RSIC-Joist isolator is designed to support a 2×4, 2×6, 2×8, 2×10, 2×12 on end. This allows you to build a floating stage/floor to separate the floor from the floor. It also allows you to build bass traps in the floor to control noise within your space. The RSIC-Joist Isolator typically is spaced at 24″ intervals on every stud/joist for your floating floor. The RSIC-Joist Isolator is made from a TPE type rubber ensuring consistent performance over the life of the isolator. You might see these used in home theaters, Band stages, performing arts theaters, private voice over, or vocal booths.

Click here to go to the product page.

Does good STC on a wall equal good STC & IIC on a ceiling?

I have been reading online about high performing STC wall noise control products. How much added noise control do I get when add them to my RSIC-1 ceiling system?

The short answer is, It has not been fully tested. The current belief is that if something works on a wall, it must work on a ceiling. Unfortunately in the world of acoustics, that logic does not always apply. There are conflicting reports online and published that may be addressed here.

Lets start with the basics of noise. Mass, Resiliency and absorption controls noise. This is an oversimplification of noise control.The best systems apply all 3 of these methods.

Walls are unique in the way that the gypsum board is held compared to the how the noise acts on the gypsum board. Typically the weight of the gypsum board is being held up, and the noise is applied to the broad side of the board. Imagine setting a piece of gypsum board on end then holding it up with 1 finger. That is totally possible. Now move that gypsum board slightly back and forth. This is how noise (vibrations) are applied to the gypsum board on a wall. Because the weight is being balanced, the amount of isolation/decoupling needed is low. All the noise control product has to do is manage the light back and forth of the gypsum board. This is why you see some success with RC-1 channel, Visco elastic products, Visco elastic gypsum boards, and isolation clips. The performances here have some large variables from STC 46 to 64. There is a large range of wall systems that can be effective for your projects.

Ceilings are different. Lets look at the same type of example we used above. Take the gypsum board that was resting all its weight on the ground (edge), and now hold it over your head. Unless you are quite the workout buff, this is fairly hard to do. Now imagine the degree of energy needed to hold and move that same board. Gravity has changed how that same piece of gypsum board reacts to the same/similar energy. That gypsum board that you so easily moved with one finger in our wall example, now is an immovable object, not really but its very heavy. All the weight is loaded on the same plane that the noise is trying to pass through. The entire weight of the ceiling has to be fully decoupled and isolated for any chance at a good acoustical result. This is where we see some separation in products. If you were to rate the options, best first: 1. Spring isolation 2.Rubber isolation 3. Channel Isolation 4.Mass and or Visco elastic products. The mass and visco elastic products are listed even here, only due to a lack of real test data for those products on ceilings. More testing is needed on the visco products to warrant a true placement in this short evaluation. By no means am I discounting the visco elastic products, only stating that there needs to be more testing.

Isolation clips with mass is currently the least expensive, highest performing option for a successful noise control ceiling system. The implementation of increased mass along with the correct isolation system, whether it be a rubber, or spring based isolation is where you see the best gains in acoustical performance.

I am sure there are plenty of arguments to this online. Here at PAC we rely on test data. When new test data is available we can revisit this.

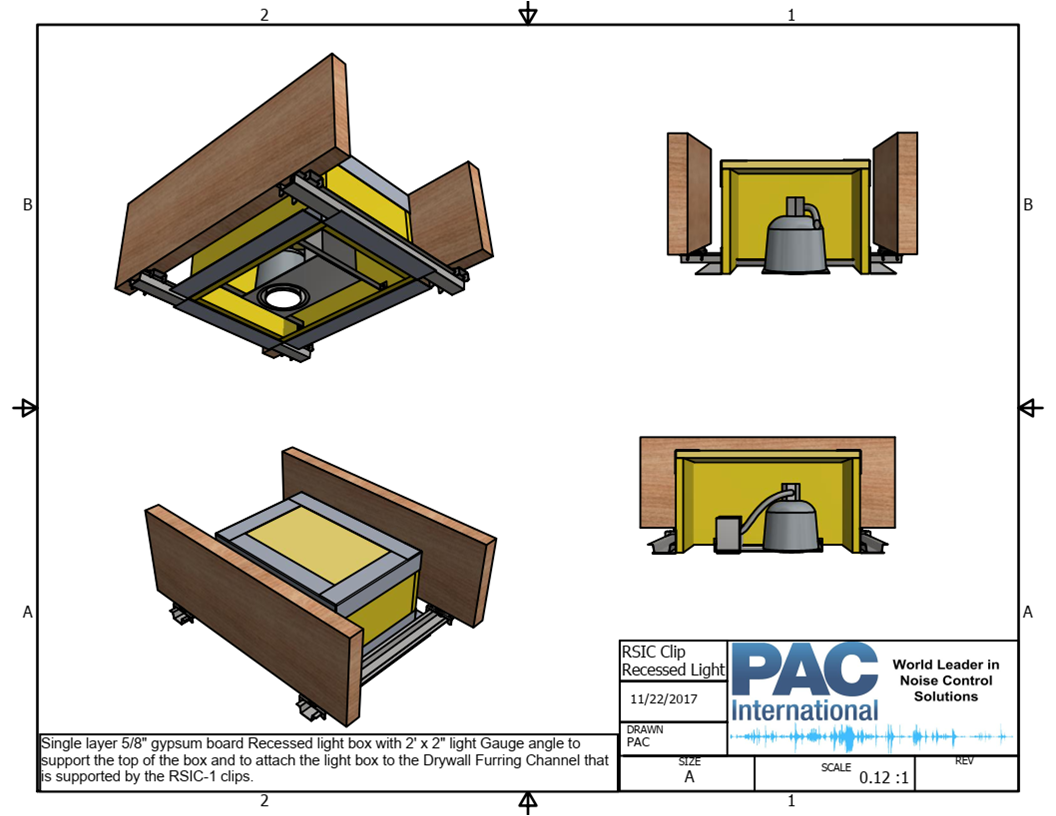

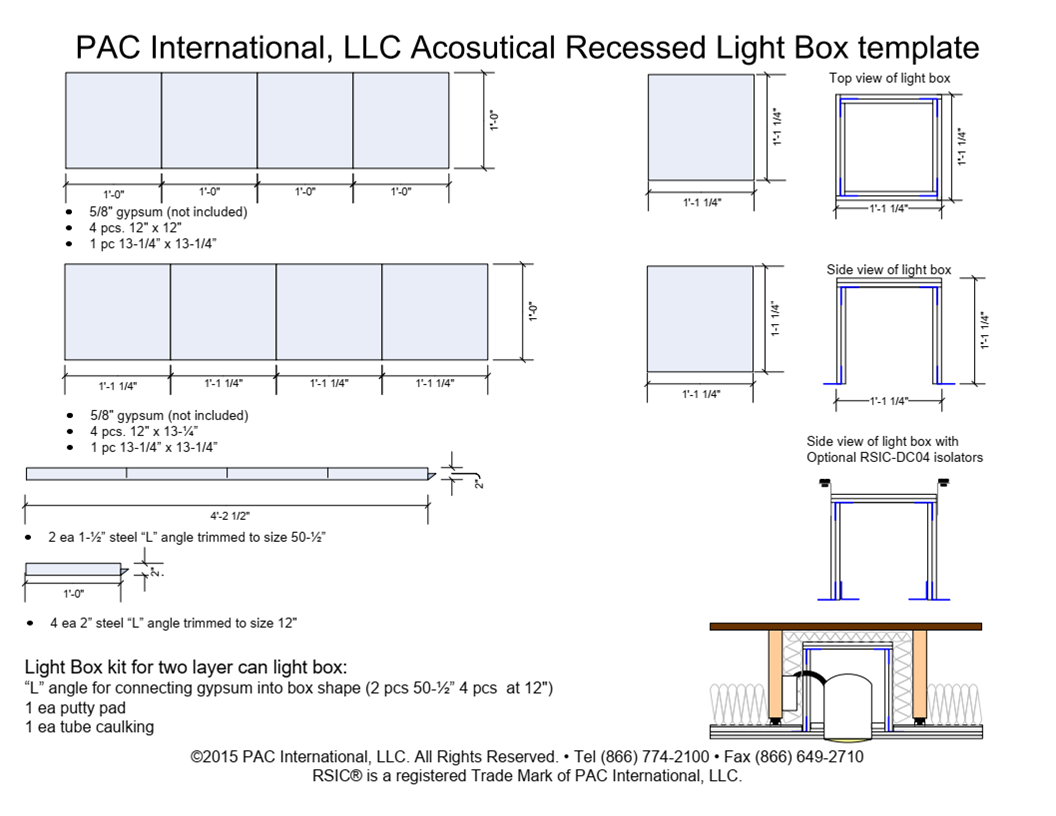

How do I add recessed light to my RSIC ceiling?

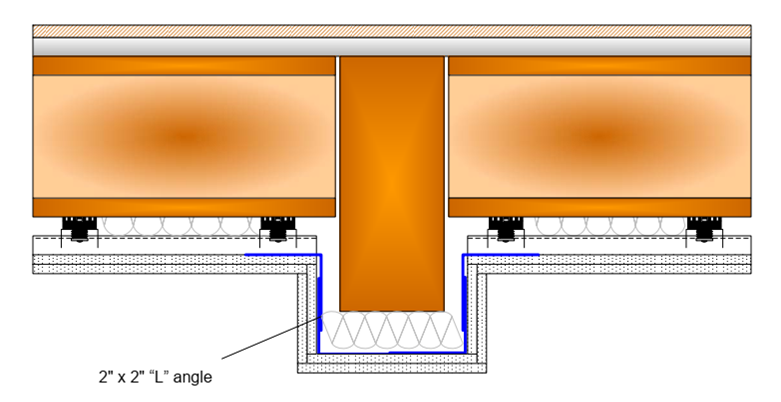

Recessed lights can be difficult. There is not an acoustical tested off the shelf answer to this issue. The addition of a recessed light can be very damaging to the acoustical performance of your ceiling. Typical recessed light fixtures have vents to let heat out, these vents also let noise in. PAC has addressed this issue by showing a gypsum board acoustical box to hang the Recessed light in. This box hangs off the Drywall furring channel that is supported by the RSIC-1 clips. The Light box can also be supported by RSIC-DC04 isolators.

This is a basic design and will allow for the installation of your standard or LED recessed light fixture.